PCB assembly

Professional electronics production (EMS) – serial and sample production

We specialize in PCB assebling of medium-sized series, but we can also produce prototype PCB assembling.

We offer our service and products at a high technical level, corresponding to the latest trends in electronics development. There is a team of specialists with many years of experience in the field.

We offer complete services, which include PCB design, production of prototypes and subsequent series, board assembling, including the supply of necessary components, testing and final assembly and packaging. PCB assembling is carried out according to the IPC-A-610 standard by our certified employees.

Our advantages are

- Individual approach

- Certification according to IPC-A-610

- Own SMT assembly line

- Serial and prototype assembly

- A team of experts with many years of experience

We have been engaged in the assembly and production of electronics since 1992, we have been operating our own assembly line since 2009. We have a large number of successful projects, both small-volume, ie orders with a development time of several weeks, and larger orders with a development time in months.

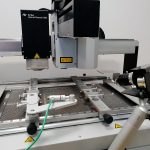

Automatic Stencil Printer

Fully automatic stencil printing PBT FA23 is used for printing pastes and adhesives.

- max. PCB size 410 x 405 mm

- color camera system – 2 cameras, 27x magnification

- surface inhomogeneity filter

- uniformity of applied paste volume and process stability

- centering system via stencil

- pneumo-hydraulic separation of the table from the stencil (it is characterized by an extremely smooth initial phase of separation, important for printing surfaces for small chips)

- control of squeegee pressure, squeegee speed, separation speed, print tear size

- print sequence – 1 or 2 crossings, with / without vacuum

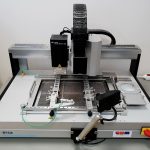

PCB Assembly

We offer SMT assembling on 2 assembly machines Autotronik BS384V1 and BA389F3 .

The machine also has a dispenser for applying paste or glue, so no template is needed for prototype and small series production.

- max. board size: 270x350mm

- SMT components sizes 01005, 0201 and larger

- capacity 10,500 components/ hour

- component dimensions min. 0.4 x 0.2mm; max 150 x 100mm

- optical centering of components

Vapour Phase Soldering

Vapour soldering is made on the BLC 420 device.

- soldering in an inert atmosphere

- max. board size 450 x 540 mm

- high soldering quality (heat transfer by condensation method allows even heating of the printed circuit board)

- possibility of soldering leaded and lead-free components (up to 0201 and 01005)

- soldering according to predefined soldering profiles (linear, saddle profiles, profiles with a transition to a small temperature gradient just before melting)

- soldering of double-sided boards

- curing the glue by infrared preheating

- PCB preheating before insertion into vapour

- PCB cooling down before exiting the device

- fast PCB cooling system immediately after reflow in the process chamber to eliminate inhomogeneities in the soldered joint

Automatic Optical Inspection

The Marantz inSpector HDL 350 is used for automatic optical inspection.

- main camera with 2Mpix resolution and 20um telecentric lens

- 8 side cameras for short-circuit detection under components

- max. PCB size 350 x 250 mm

- detection of missing components from size 01005 and solder quality from 0201

- detection of raised, rotated and shifted components

- polarity detection, values (color bars and text), component type

- detection of soldering quality and short circuits between terminals

- even lighting + 3 LED lighting sources at different angles

- image evaluation using synthetic modeling based on a reference image

- spectral analysis of the image – histogram, evaluation of hue and saturation

- viewing and archiving of found errors (type, number, picture…)

Cleaning

A MINICLEAN dishwasher is used to clean the assembled printed circuit boards.

It is a device for cleaning electronics after soldering, misprints, stancils or large-format substrates.

For cleaning, a full-area sub-surface spray is used, followed by a rinse in drinking water, a rinse in DI-water and finally drying with hot air.

In all individual phases, the quality of the filled media or conductivity is automatically checked. DI water filtration is performed up to the level of 1 micron. Drying is made to a maximum temperature 90 °C.

Drying

For drying and storage of electronic components we use automatic dry cabinet MP DRY CABINET I ST.

- powerful heating, which allows you to reach a drying temperature up to 60 ° C

- maintaining a very low relative humidity below 0.5% RH

- storage of PCB and MSD components of all classes without the need to re-vacuum in MBB bags

- complies with IPC / JEDEC J-STD 033C (component storage) and IPC-1601 (PCB storage)

- equipped with a data logger function with internal memory for storing data on the internal temperature and relative humidity over time

- low energy consumption

Rework System

The Ersa HR600 Rework Station is used to repair or replace soldered (especially BGA) components.

- max. PCB size 390 x 285 mm

- component size 1 x 1 mm to 50 x 50 mm

- bottom IR preheating system

- fully automatic component replacement

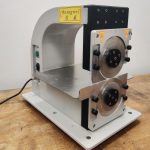

PCB depanelization

Depanelization of printed circuit boards, which are divided by a V-groove